Introduction:

Insulating or exothermic sleeves are used to increase the yield in foundry practice. Each of the sleeve manufacturer provides a large variety of sleeves in different sizes. Function of sleeve is predominantly to enhance the effective casting modulus by increasing feeding efficiency. This is represented by a modulus extension factor (MEF). Details studying the effectiveness of feeding aids are given in IS 15865:2009 and such similar standards.

A methoding / gating designer has to decide for a given casting application

- which is the best type of sleeve?

- where the sleeves have to be located?

- how many such sleeves needed?

Often, new entrants into the casting process design, who lack experience and knowledge, are faced with a difficulty of making the appropriate choices of sleeve to increase yield in casting. There will be problems to evaluate the feed safety margins, volumetric feed efficiency of various sleeves to make the right choice. Casting simulation software can help in making such decisions. Further casting simulations help to make the decisions faster, and with more accurate data. Such information coming out of casting simulation will be very useful even for experienced methods developer. Simulations can help to reduce the feed safety margin and use simulation to develop process control parameters.

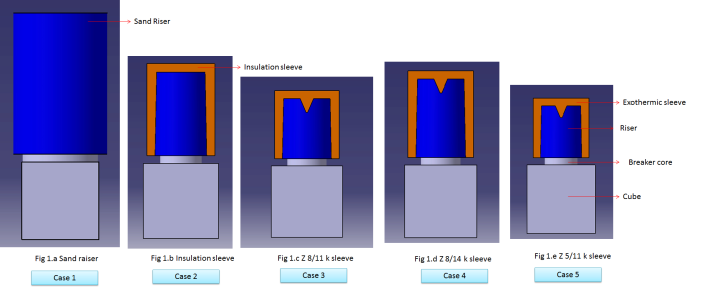

Authors demonstrate the usage of a casting simulation software ADSTEFAN for studying the effectiveness of sleeves and demonstrate how yield improvement can be enhanced. To demonstrate the concept a simple casting of a cube is taken for analysis. Five cases of different sleeves are considered for demonstration sleeve effect on shrinkage porosity formation.

- Without any sleeve (sand riser)

- With insulating sleeve (Insulation sleeve)

- With exothermic sleeve (ZP 8/11 K Foseco Kalminex 2000plus sleeve)

- With exothermic sleeve (ZP 8/14 K Foseco Kalminex 2000plus sleeve)

- With exothermic sleeve (ZP 5/11 K Foseco Kalminex 2000plus sleeve)

Figures 1a to 1e represent these cases for different sleeves used.

Casting Simulation to study the effectiveness of sleeves

Authors use a commercially available ADSTEFAN (developed by Prof Niyama of Japan). All cases are considered for material 0.4% C_ Steel and pouring temperature1560 C. Results of solidification and shrinkage porosity formation are given in Figure 2a to 2e. Figure 2 shows the height of the porosity area, including the additional height of the riser considering the factor of safety/ safety margin (conventionally taken as 80% of the riser diameter). In the figure, the red regions show the regions of shrinkage porosity. Blue represents the fully solidified metal region.

Correlation of simulation with physical casting:

Many of the users of casting simulation software complain about the lack of good correlation between simulation and plant data. In foundries such deviations between plant production and simulation software are seen mainly due to:

- Improper inputs to the software

- Lack of proper training for using simulation software,

- Inadequacy of the simulation software

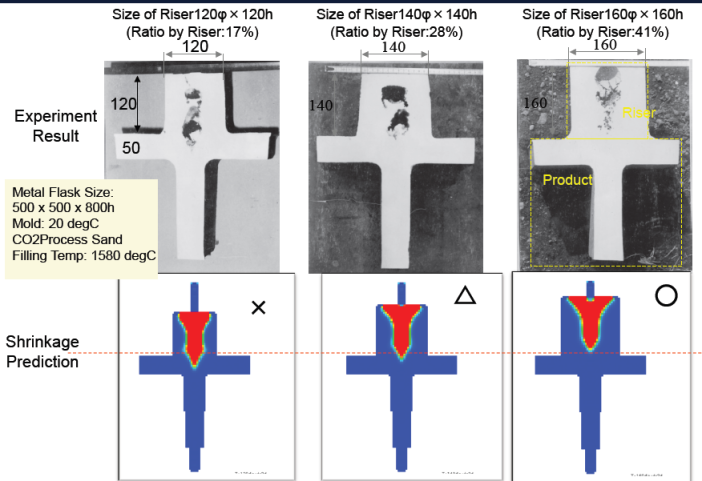

If these issues are addressed, quite a good correlation can be achieved by casting simulation results and plant observation of casting defects. Figure 3 shows comparison of physical castings with the corresponding ADSTEFAN casting simulation results. In left side of figure 3, the defect is penetrating deep into the product. In the figure in middle, the shrinkage has just penetrated casting and is still risky. In the right figure, the casting does not have any defect. These 3 case, demonstrate good correlation between simulation using ADSTEFAN and physical castings.

Results: Simulating Effectiveness of Sleeves

Table-1 shows the calculation of yield for all the 5 cases. In the case-1, a sand sleeve is used and obviously the casting yield is the lowest at 30%. In case-2, a normal insulating type sleeve is used, and the yield increases to 55%. Yield will increase to 25 % when we use a casting sleeve of type insulating sleeve.

Case-4 shows the usage of an exothermic sleeve which has a higher MEF compared to case-3. As a result, as seen in figure 2, no shrinkage porosity is formed. However, for this casting such a sleeve is an over kill and the yield is reduced.

Case-5 shows the usage of an exothermic sleeve which has lower MEF compared to case-3. As a result, as seen in figure 2, a shrinkage defect is formed there is no margin of safety available. It will be risky to produce the castings with this sleeve.

Table-1: Effectiveness of sleeve for yield improvement.

| Case | Sleeve type | Sleeve height | Porosity height | Safety Margin Height | Yield % | Remarks |

| Case-1 | Sand Riser | – | 147 | 75 | 30 | |

| Case-2 | Insulation sleeve | 128 | 111 | 29 | 55 | |

| Case-3 | Exothermic sleeve (ZP 8/11 K) | 109 | 69.5 | 27 | 78.18 | Best Optimised Sleeve |

| Case-4 | Exothermic sleeve (ZP 8/14 K) | 138 | 78 | 72 | 62.58 | Good. But not best optimised |

| Case-5 | Exothermic sleeve (ZP 5/11 K) | 110 | 159 | 67.77 | Shrinkage formed |

Conclusion:

Casting simulation results (using ADSTEFAN software) have been shown to be correlating well with the physical castings produced. From the casting simulation results, it is seen that for casting of a cube, sleeve ZP 8/11 K (or equivalent) is the best and optimum. For each casting component, using simulations, best sleeve choice can be determined, for that material, shape, and process conditions. If the process can be tightly controlled, simulation gives clues on how much the feed safety margin can be reduced, to increase yield further.

For more details on our R&D services, log in to www.pro-sim.com

For a better insight of our technology, Email Us